Advanced Macromolecular Resists (A3)

Advanced resist design is required for 3D laser lithography (also known as Direct Laser Writing (DLW)). In close alignment with Thrust B1, we will provide the chemical tools to tackle the challenges that will allow us to implement the next generation 3D Additive Manufacturing processes as recently described here: https://onlinelibrary.wiley.com/doi/full/10.1002/anie.201704695.

The Thrust is guided by our efforts of fusing four chemical challenges into one resist. We wish to code free-standing sub-diffraction structures (in the sub-20 nm range) with two different colors of light. Such structures will carry predetermined materials properties, reaching from insulating to highly conducting as well as (bio-orthogonally) degradable. In alignment with Thrust B1, which provides the 3D laser lithography machine tools, the ultimate aim of Thrust A3 can be subdivided into four individual aims:

1) development of effective sub-diffraction resists, 2) degradable resists, 3) conductive resists, and 4) resists that can be orthogonally written with different colors of light, affording disparate material properties (multi-material resists).

Close alignment with the molecular building blocks designed in Thrust A1 will ensure that we meet the molecular targets. Ultimately, the technologies developed in A3 in conjunction with B1 are critically required to achieve nanometer sized functional features that are essential for the constructs of Research Area C.

Prof. Dr. Christopher Barner-Kowollik

Karlsruhe Institute of Technology

Prof. Dr. Uwe Bunz

Heidelberg University

Please also note our dedicated Opportunities page.

Images

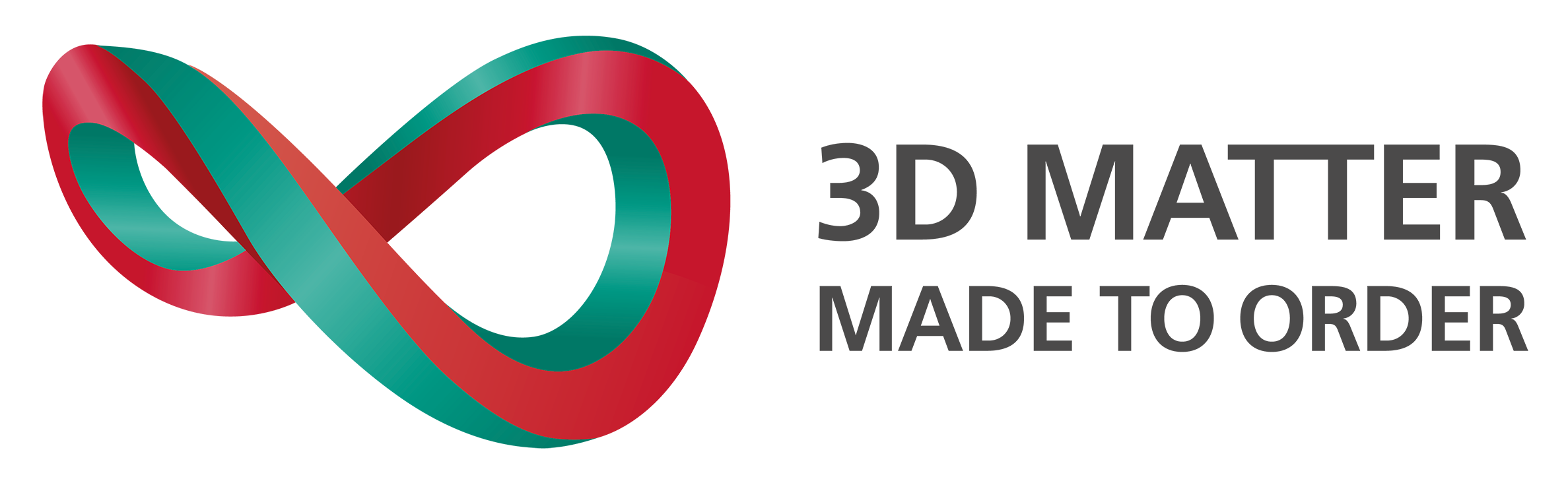

Description: Immobilized Poly(arylene ethynylenes) on a nylon membrane under UV light – showing their brightest fluorescence colors. (Source: Maximilian Bojanowski)

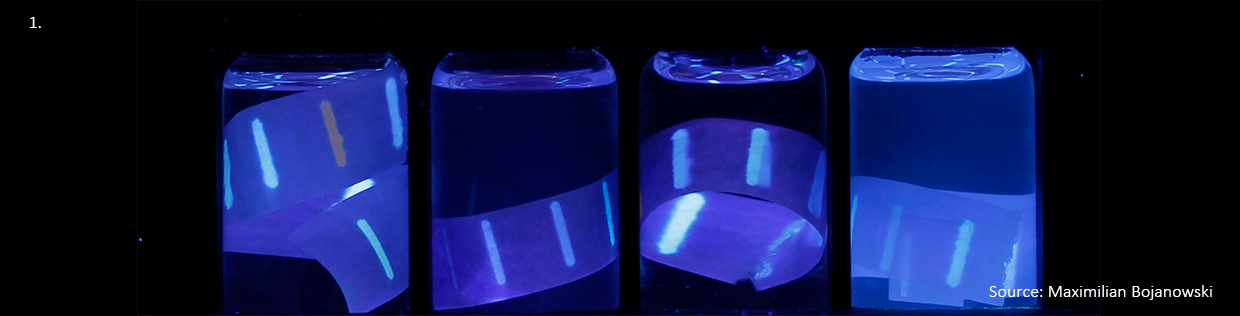

Description: Nanosized structured Cinnamic acid derivatives on native silicon. Selective Cycloadditions under electron bombardment towards 3D networks. (Source: Maximilian Bojanowski)

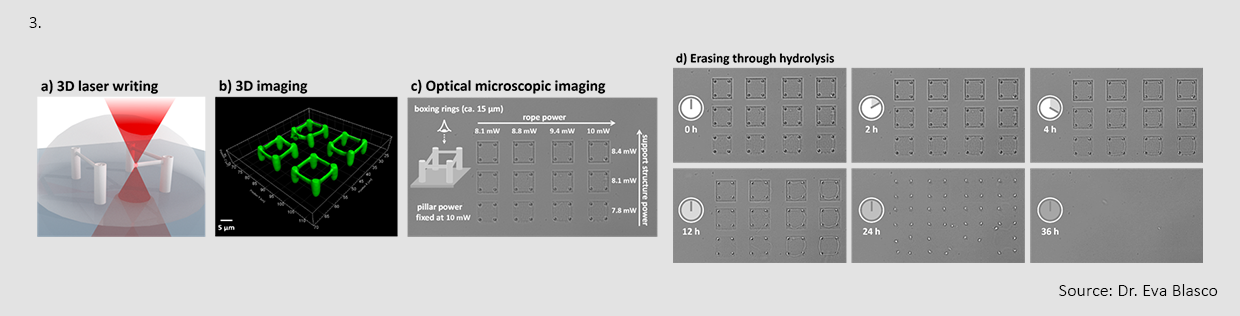

Description: A novel polyethylene glycol-based photoresist that allows for the fabrication of microstructures that can be readily erased in water has been developed. a) Schematic representation of micrometric structures (15 × 15 × 5 µm3) using 3D laser lithography. b) Laser scanning microscopic 3D reconstruction of the written microstructures. c) Optical microscopic image of a series of microstructures, written at varying laser powers. d) Time-lapse optical microscopic imaging of the microstructures being erased upon immersion in water at 37 °C. (Source: Eva Blasco; Houck et al. Adv. Mater. 2020, 2003060