3D Matter Made to Order

Cluster of Excellence of Karlsruhe Institute of Technology (KIT) & Heidelberg University

3D Additive Manufacturing Driven Towards the Molecular Scale

The Cluster of Excellence is a collaboration of Karlsruhe Institute of Technology (KIT) and Heidelberg University (Uni HD). It pursues an interdisciplinary approach through conjunction of natural, engineering, and social sciences. 3DMM2O establishes scalable digital 3D Additive Manufacturing transcending from the molecular to the macroscopic scale.

This approach converts digital information into functional materials, devices and systems “made to order.” 3DMM2O creates a powerful technology push and pull by treating molecular materials, technologies and applications as indissolubly intertwined.

On the technology side, the scientific challenges are “finer, faster, and more”, i.e., advance molecular materials and technologies in terms of resolution, speed, and multi-material printing by orders of magnitude.

On the application side, we aim at functional 3D hybrid optical and electronic systems, 3D artificial materials called metamaterials, and at reconstructing functioning organotypic systems by using 3D scaffolds for cell culture.

Prof. Dr. Martin Wegener

Karlsruhe Institute of Technology

martin.wegener@kit.edu

Prof. Dr. Christine Selhuber-Unkel

Heidelberg University

selhuber@uni-heidelberg.de

News

Recap Cluster Conference 2024

Our annual 3DMM2O Conference took place at Schöntal Monastery in April. A very exciting program was put together: In addition to the PIs and Doctoral Researchers, an excellent selection of invited speakers gave presentations. During the five-day conference, there were also plenty of networking opportunities and exchange during the poster sessions or the social program. Get some impressions of this year’s conference!

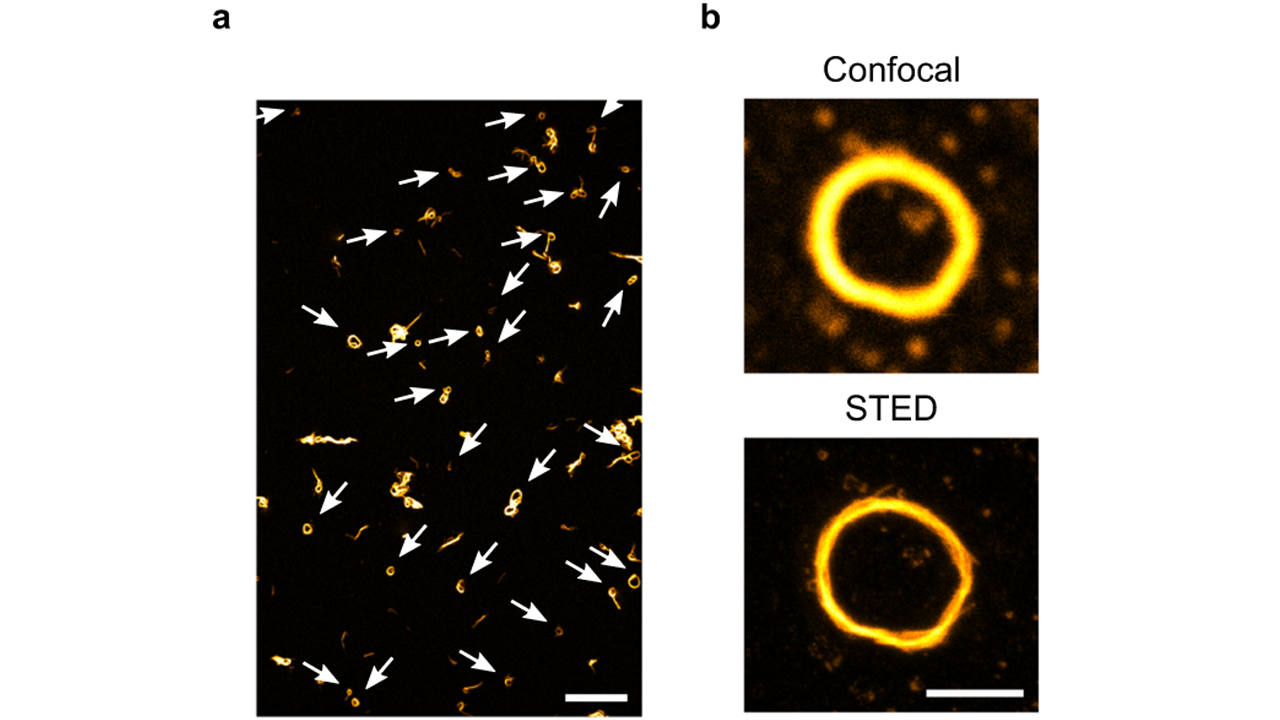

A first in artificial cell division!

Cluster Alumnus Kevin Jahnke is second author and Cluster PI Prof. Dr. Kerstin Göpfrich is co-author of a pioneering paper published in Nature Communications. The research team succeeded for the first time in developing a ring of DNA nanotubes that could be used for artificial cell division. The results have provided new insights into the formation of DNA nanotube rings and the architecture of their contraction mechanism. Findings based on DNA-based contractile rings could be used to create artificial machines for dividing or contracting muscle-like materials.

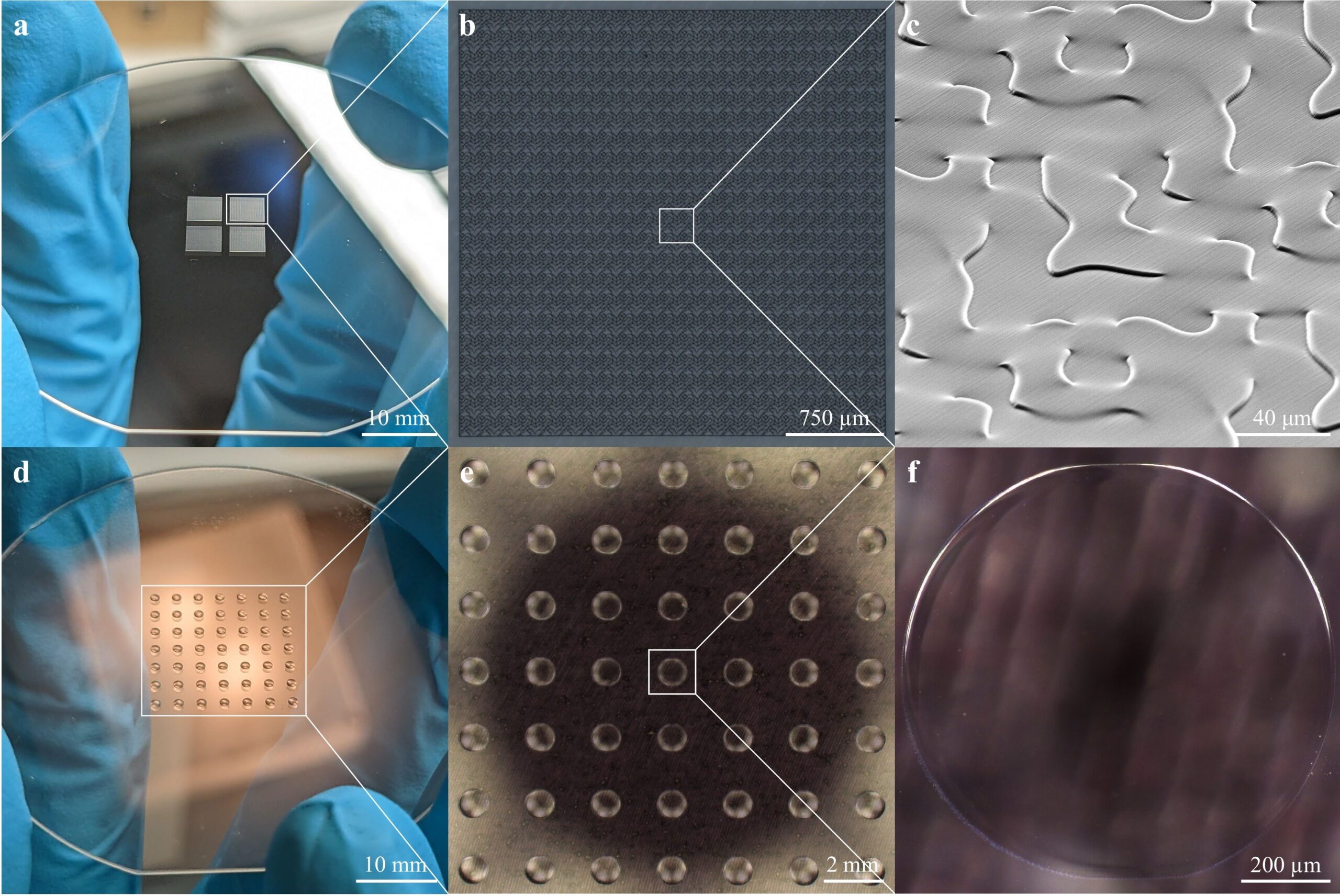

New setup increases speed of multi-photon 3D laser printing

A new Cluster publication by first author Dr. Pascal Kiefer addresses one of the key challenges of multi-photon 3D laser printing. The scientists have developed a new setup that allows printing speeds to increase 10-fold. The combination of the large array and fast scan speeds means that very large or small samples can be produced in large quantities at a high 3D printing rate. This opens up the possibility of new studies, for example in the field of respiratory drug delivery, where some sample requirements were previously unachievable.

Recap Winter Cluster Meeting 2024

In March, the Cluster members met for the yearly Winter Cluster Meeting at Kloster Neustadt. During the two-day event, there were presentations by Principal Investigators, insights into Postdoc Take-Off Grant projects, poster sessions and a lot of room for networking and scientific discussion. It was a great pleasure to see and talk to you!

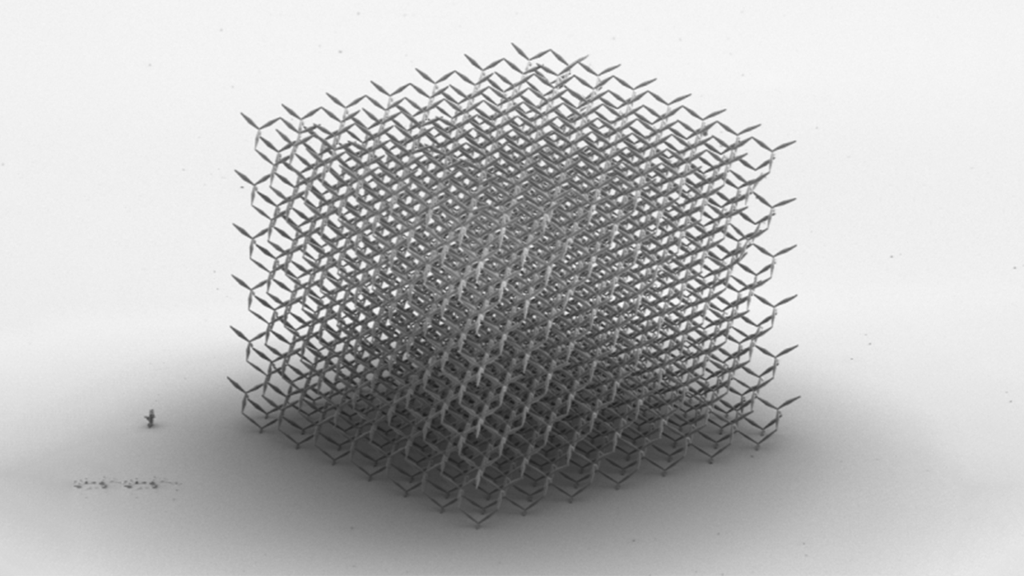

Prof. Dr. Graeme Milton gives a Lecture on Metamaterials at the APH

Prof. Dr. Graeme Milton from the University of Utah gives a lecture titled “From Pentamodes to Cable Webs to Masonry Structures” at the Institute of Applied Physics (APH) of the Karlsruhe Institute of Technology (KIT) on Friday, March 8, 2024. In his lecture, he will show how to design discrete networks that mimic the stress-guiding properties of pentamode materials, with applications in obstacle avoidance and masonry-inspired structures. In 1995, Milton and Andrei Cherkaev predicted the existence of pentamode materials, which are solids that behave like liquids. In 2012, Cluster PI Martin Wegener developed a process to produce these materials using 3D printers. The lecture will take place from 2 p.m. to 4 p.m. at room 6-1.

Continuation Application goes to the Final Round

The renewal application for the Cluster of Excellence 3D Matter Made to Order, which has been funded since the end of 2019, is entering the final round. The application must be submitted by August 22, 2024. In May 2025, the Excellence Commission, made up of the members of the expert panel and the federal and state science ministers, will make the final decision on which Clusters of Excellence will be funded in the future. Funding will begin on January 1, 2026 and will run for seven years. The aim of the Excellence Strategy is to strengthen Germany as a science location in the long term and to further improve its international competitiveness.